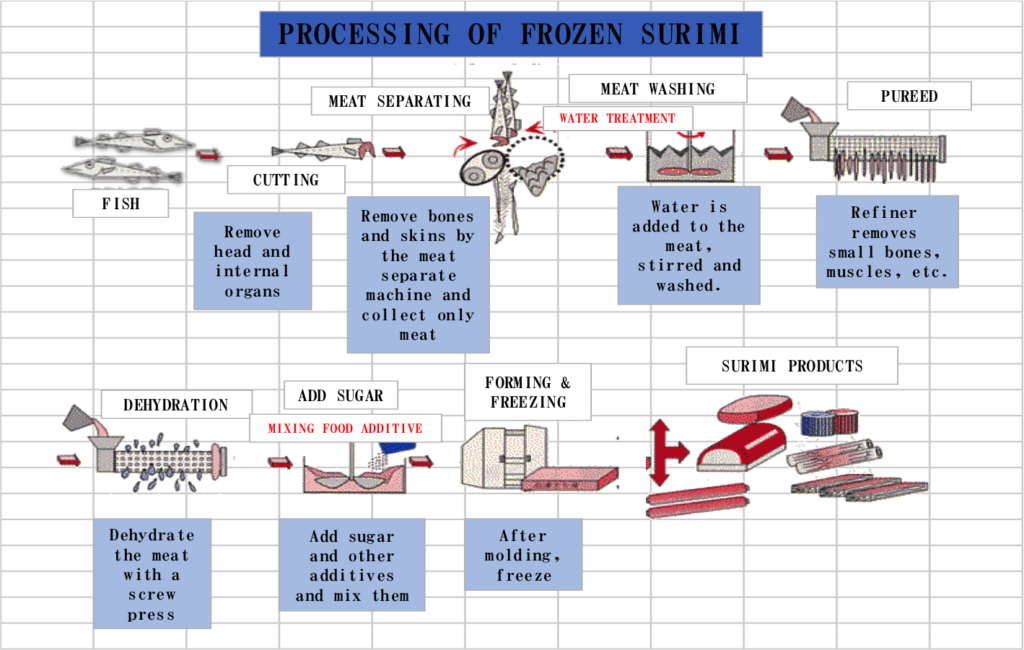

surimi processing steps

The screw press product press cake was blended with sugar 4 ww sorbitol 4 ww and polyphosphate 015 ww and pyrophosphate. Surimi Processing 1 Critical Control Point CCP 2.

How It S Made Surimi Surimi Production Youtube

Surimis Processing Get in Touch.

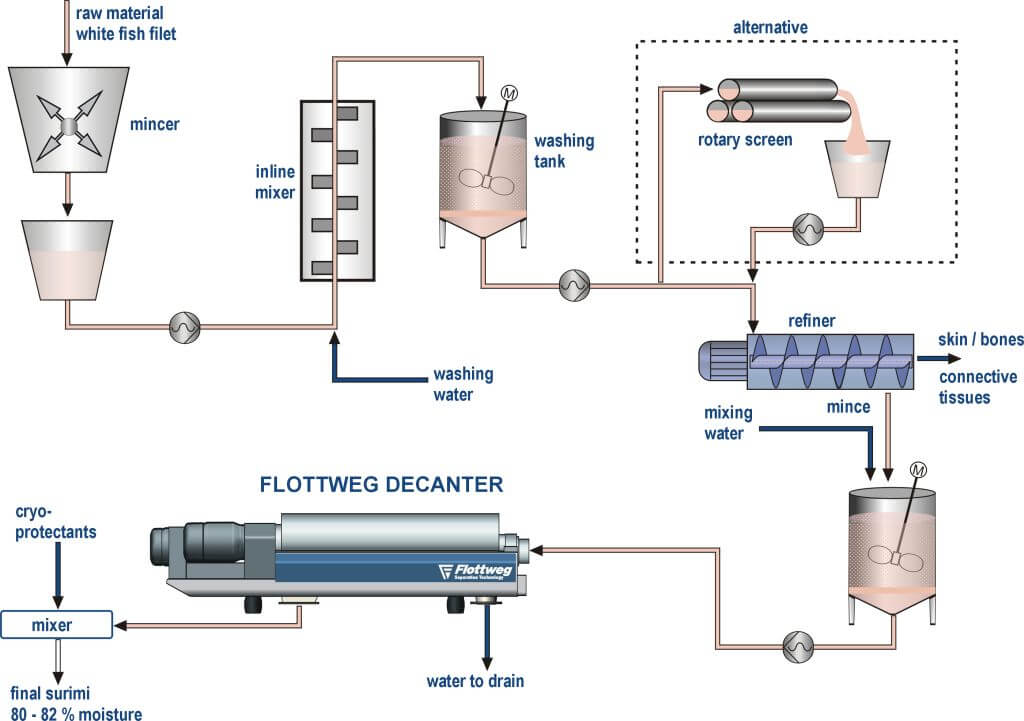

. The process of claim 1 wherein the crushing step is accomplished by a mince crushing device including a mincer drum. Further during surimi processing after washing and dewatering process about 40 to 50 of solids are lost from minced fish and more than 75 of wastewater discharged containing 046 to 234 of total protein including myofibrillar proteins from screeners screw processors and dehydrators. Surimi in an on-shore processing plant.

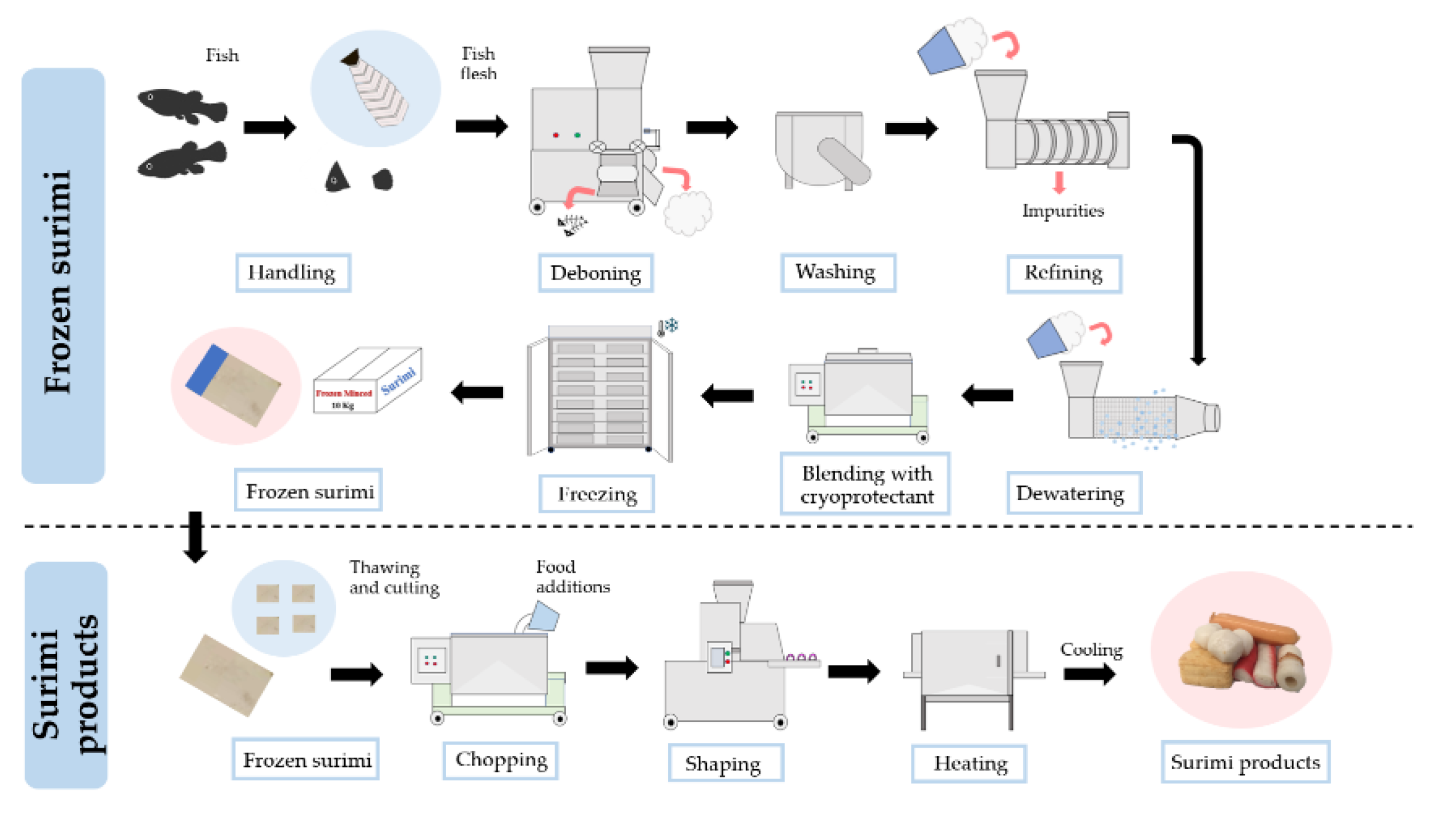

The product known as Frozen Surimi is minced fish flesh gone through washing with water draining the water mixing thoroughly with sugar and. The muscle is then minced by passing the material through a perforated screen and collecting the mince. Surimi processing technology involves the washing of minced fish in order to purify and concentrate the muscle proteins which may be.

With an Alfa Laval surimi solution fish processing operations get greater recovery and thus greater profits from any catch. The gel forming ability of fish for processing of surimi also varies greatly from fish to fish and depending on temperature conditions. Fish heads are removed guts are cleaned and bones are removed with large amounts of water to separate the waste material from the muscle tissue.

The optimal chopping parameters are 1 500 rmin rotation speed 2 min air chopping and 2-4 min salt chopping but the texture and gel properties are still inferior to the beat-prepared products. These authors found 871 for L and 75 for b in the surimi made of golden threadfin bream Nemipterus virgatus with 78 moisture and Galvão et. The minced fish meat is then washed with chilled water repeatedly to remove the undesirable pigments fats flavours and water soluble proteins primarily sarcroplasmic proteins which are thought to impede the gel-forming ability of surimi.

The process of claim 2. Gadres mission is to continuously explore new technologies for better quality Surimi. Impeccable quality and engineering ensure customers.

Manufacturing process of frozen surimi on board 1Unloading process. 2Fish meat separating process. Effective processing of surimi is an intricate process with multiple steps from fresh fish to processed cleaned washed drained and frozen in surimi blocks.

Was founded in 1993. Introduction Surimi is Japanese term commonly used for minced fish flesh obtained after necessary processing steps. Surimi manufacturing process 1.

Including the AlfaPlus surimi processing line in which advanced centrifugal separation technology replaces the rotary screens and. Call us on 95 1 3684181-5. Surimi is a refined form of mechanically deboned fish meat that has unique functional characteristics including gel-forming ability water and oil binding properties which make it a valuable ingredient in a broad range of food products.

Surimi manufacture is a multi-step process as shown in Fig. The final dewatering step used a Fukoku HX-150 screw press. Surimi processing on limited space Adding surimi processing to the onboard factories is trending in the fishing industry.

Mechanical processing steps Metal detector Yes Freezer BIOLOGICAL None No NA NA No CHEMICAL None No NA NA No PHYSICAL None No NA NA No Ship BIOLOGICAL None No NA NA No CHEMICAL None No NA NA No PHYSICAL None No NA NA No Reviewed by. Surimi Technology Additives Quality Alaska pollock. Since the beginning of 1980 when surimi-based products were first introduced into the US market with explosive response the surimi analogue production showed an exponential growth from a mere 2760 metric tons mt in 1983 to 80 000 mt in 1990 NMFS 1991 while the surimi production from Alaska pollock has risen from 58 200 mt in.

Gadre Marine ensures 100 quality for the entire surimi producing process. SURIMI PROCESSING HOW TO CUT FISH FOR OPTIMIZING SURIMI QUALITYWe are consulting supply machine instaltion factory contact. About us Min Zar Ni Co Ltd.

Firstly the fishes are cleaned deboned and minced. Process a wide range of different fish species. A process to produce higher grade surimi from the flesh of fish using less fresh water comprising.

In the process of surimi crushing chopping will make the particle size of surimi first decrease and then increase. Fish processing operations result in many leftovers that are traditionally considered relatively low in value. Saves both space and manpower.

After catching the fish we have put them into the tank and sorted out after unloading them in the. Consistently high hygiene standards. Return to Index 5.

After removing head visceral parts bones and. Preparation of Surimi Beheaded eviscerated and skinned Washing with cleaned chilled water Filleting by knife Deboning Mincing Washing Fish 01Nacl solution for 5- 8min. Maximum recovery for a higher yield.

The first pioneer plant was established in 1995 in Yangon and at the present time we have three factories along the coastal fringe of Myanmar located in Yangon Hlaing Thar Yar Sittwe and. There are a few major steps in processing the surimi. Most are normally turned into fish meals and other products used as components in animal feed.

How It S Made Surimi Surimi Processing Line Youtube

Manufacturing Process Of Imitation Fish Paste Download Scientific Diagram

Flowchart Of The Surimi Processing Steps Download Scientific Diagram

The Basic Of Frozen Surimi How To Make Delicious Kamaboko

Manufacturing Process Of Imitation Crab Stick Download Scientific Diagram

Surimi Processing Centrifuge Decanter Equipment For Surimi Production Zk Separation

How It S Made Surimi Surimi Production Youtube

Surimi An Overview Sciencedirect Topics

Flow Diagram Of Surimi Processing Download Scientific Diagram

Surimi An Overview Sciencedirect Topics

Manufacturing Surimi With Decanter Flottweg Separation

Surimi An Overview Sciencedirect Topics

Flowchart Of The Surimi Processing Steps Download Scientific Diagram

The Surimi Process Food Processing Barnard Health Care

Flow Diagram Of Surimi Processing Download Scientific Diagram

Appendix Vi Proposed Draft Code Of Practice For Fish And Fishery Products

Foods Free Full Text Asian Carp An Alternative Material For Surimi Production Progress And Future Html

The Surimi Process Food Processing Barnard Health Care

Appendix Vi Proposed Draft Code Of Practice For Fish And Fishery Products

Comments

Post a Comment